Euromilling's Pneumatic Solutions: High-Pressure and Vacuum Transport

EUROmilling offers sophisticated pneumatic transport solutions tailored to meet diverse industrial needs. Among the prominent options available are high-pressure and vacuum transport systems. High-pressure transport is ideal for moving materials over long distances and through complex routes with a robust flow rate. This method leverages high air pressure to propel bulk solids efficiently through pipelines, ensuring minimal material degradation and optimal transport speed. Conversely, vacuum transport utilizes negative pressure to draw materials through the system, making it particularly suitable for handling delicate or lightweight products that may be damaged by high-pressure forces. This method is also excellent for applications requiring strict hygiene standards, as the enclosed system minimizes contamination risks. Both systems are integral to EUROmilling’s commitment to providing efficient, safe, and reliable material handling solutions. The choice between high-pressure and vacuum transport depends on specific operational requirements, including the type of material, desired transport speed, and distance.

Customized Pneumatic

Transport Design and

Engineering

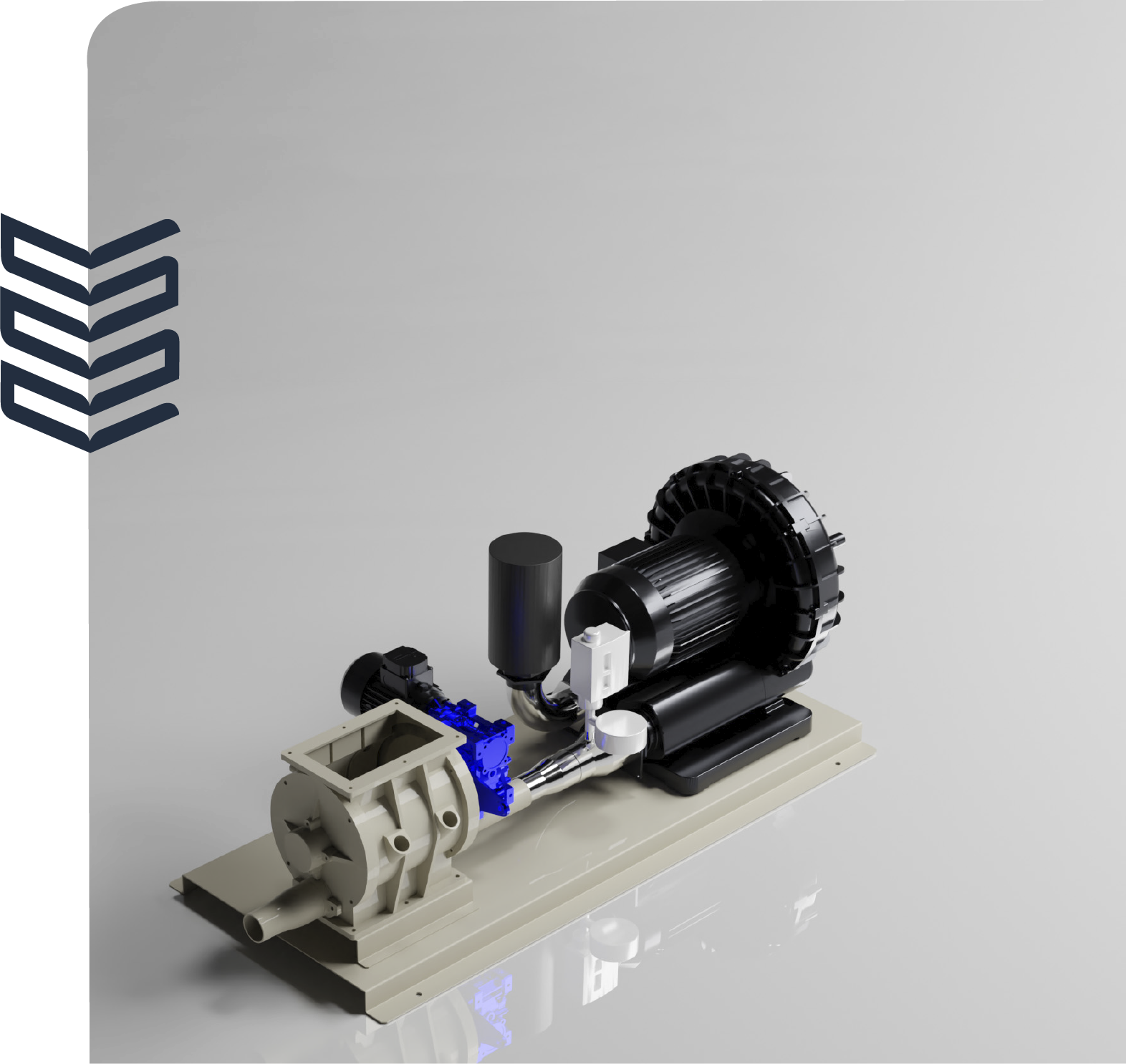

A standout feature of EUROmilling's pneumatic solutions is their customized approach to designing and engineering transport systems. This involves meticulous calculation and dimensioning of pneumatic transport elements, such as pipe sizes and bends, to ensure optimal performance. EUROmilling designs systems capable of transporting materials over distances of up to 350 meters, addressing both short and long-range transport needs. The company utilizes proprietary filters and cyclones, designed and manufactured in-house, to enhance system efficiency and durability. These components are crucial in ensuring that the transported materials maintain their integrity and that the system operates smoothly with minimal downtime. Additionally, EUROmilling provides comprehensive solutions for the filling and emptying of pneumatic transport systems, ensuring seamless integration with existing processes and infrastructure. This level of customization and engineering precision underscores EUROmilling’s commitment to delivering tailored solutions that align perfectly with each client’s unique requirements.

Integration and Supplier Collaboration in Pneumatic Systems

EUROmilling’s pneumatic transport systems are characterized by their adaptability and integration capabilities. Every system is customized to the specific product and process requirements of the client, reflecting EUROmilling's dedication to personalized service. In designing these systems, EUROmilling collaborates with a diverse array of blower suppliers, selecting the most suitable equipment to meet the demands of each unique application. This ensures that the pneumatic system not only performs efficiently but also integrates seamlessly with other components such as big bag filling and emptying stations. The ability to combine different elements into a cohesive system highlights EUROmilling's expertise in holistic design and system integration. Furthermore, the company's use of high-quality, tailor-made filters and cyclones ensures that each pneumatic system operates at peak efficiency, with enhanced durability and reduced maintenance needs. By working closely with clients to understand their specific needs and leveraging a broad network of suppliers, EUROmilling delivers pneumatic solutions that are both highly effective and precisely tailored to enhance overall operational efficiency.