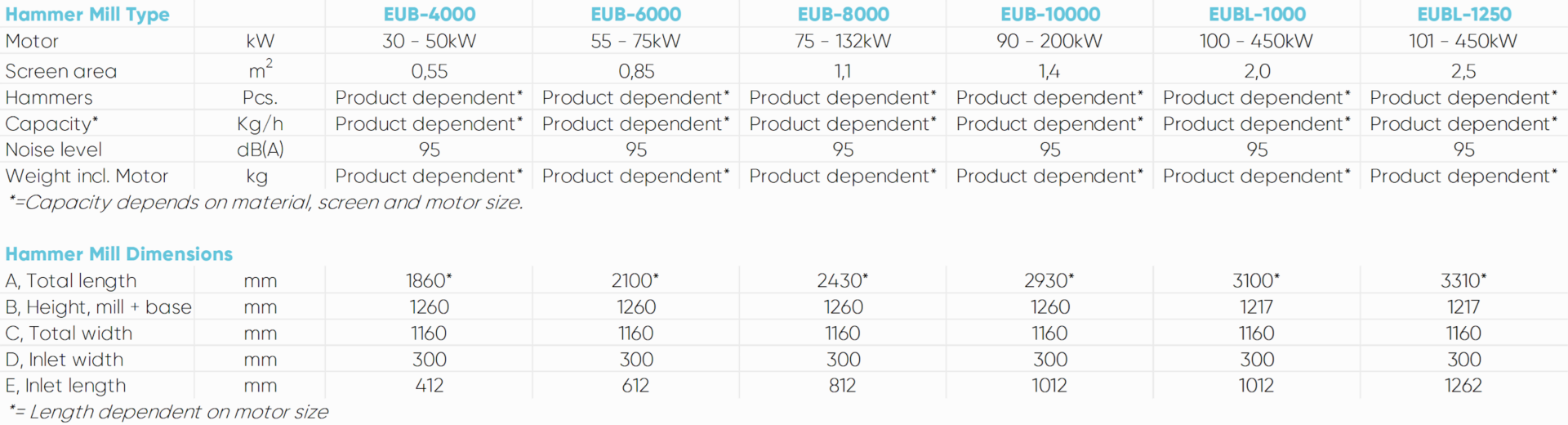

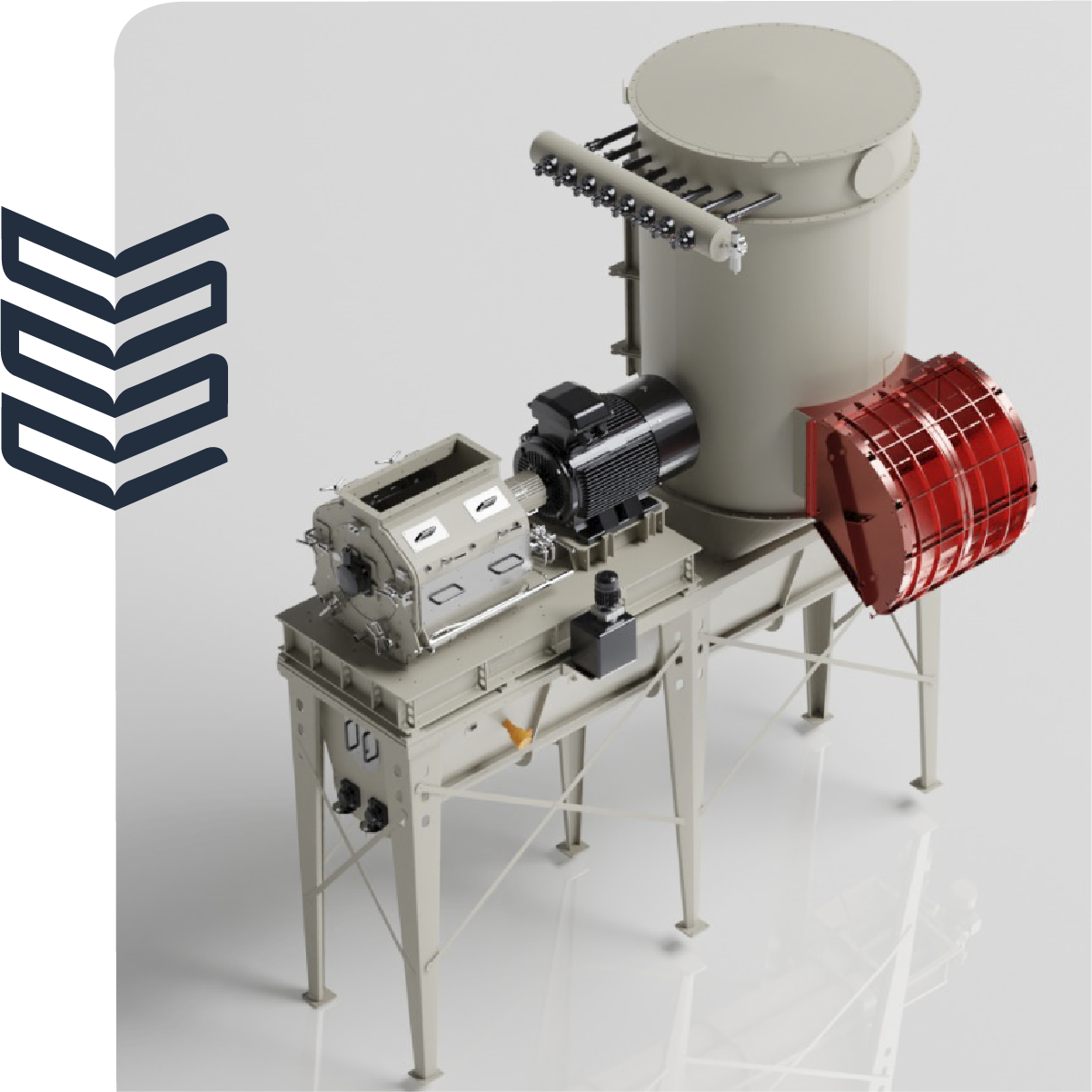

EUB Series

Over 30 Years of Expertise in Hammer Mill Development

Advanced Technology for Fine Grinding of Biomass

Consistent Performance with Heavy Rotors

Tailored for Biomass Grinding

Dual Rotation and Extended Hammer Life

Streamlined Sieving and Maintenance

Enhanced Grinding with Hardened Concave Segments

Comprehensive Monitoring and Control

Versatile Variants for Different Needs

ATEX certification

At Euromilling, we prioritize safety and regulatory compliance through our advanced ATEX solutions. Our comprehensive approach includes certified ATEX solutions, thorough risk analysis, and detailed documentation, providing a robust foundation for your operations.

Meeting Regulatory Standards

Euromilling’s ATEX solutions are meticulously designed to meet all regulatory standards, ensuring that your operations comply with the strictest authority requirements. Our teams of engineers and project managers work closely with industry professionals to deliver unparalleled safety and compliance.

Key Components of Our ATEX Solutions:

-

Risk Assessment: We conduct in-depth evaluations of potential risks associated with your project, developing straightforward strategies to ensure your operations are safe and successful. Our proactive approach to risk management sets the foundation for a secure working environment.

-

ATEX Compliance: We guarantee that your facility adheres to the ATEX directive, ensuring the safe handling of potentially explosive atmospheres. Our solutions are designed to minimize the risk of explosions and ensure the highest levels of safety.

-

CE Certificate Acquisition: Our experts assist you in obtaining the CE certificate, validating that your operations comply with essential health and safety requirements. This certification reflects our commitment to delivering solutions that meet the highest standards of quality and safety.

-

Fire Extinguishing Systems: For added safety, we implement state-of-the-art fire extinguishing systems tailored to your specific needs. These systems provide an additional layer of protection for your operations.

Additionally, Euromilling offers consultancy services for both existing and new projects, providing expert assistance with ATEX solutions to ensure full compliance and optimized safety.

Euromilling's ATEX solutions are trusted by the biomass and food industry for their reliability and effectiveness. Partner with us to ensure your operations are safe, compliant, and prepared for any challenge.

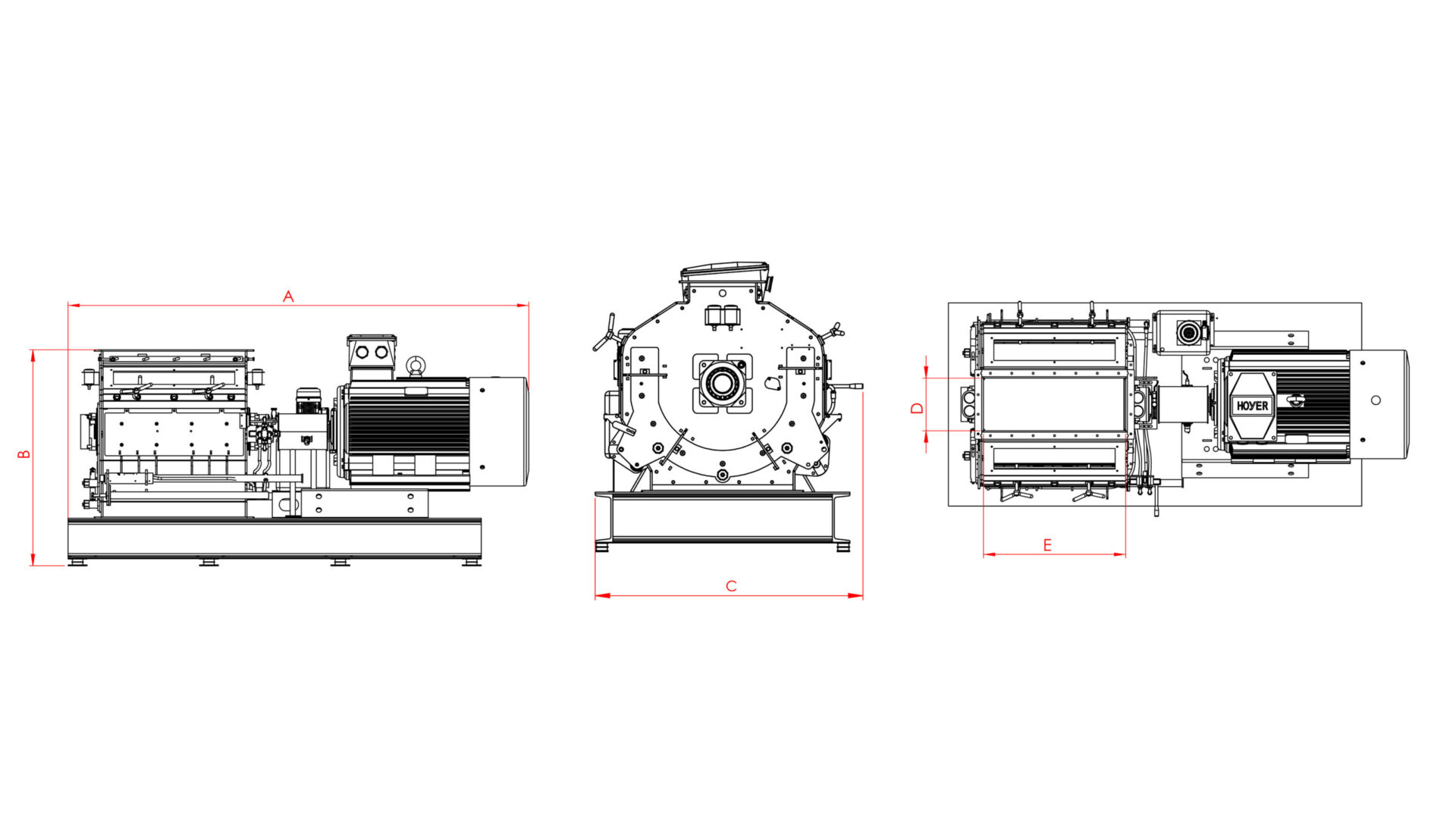

Technical Data

EUB Series