Roller Mill

Advanced Crushing Technology for the North Sea

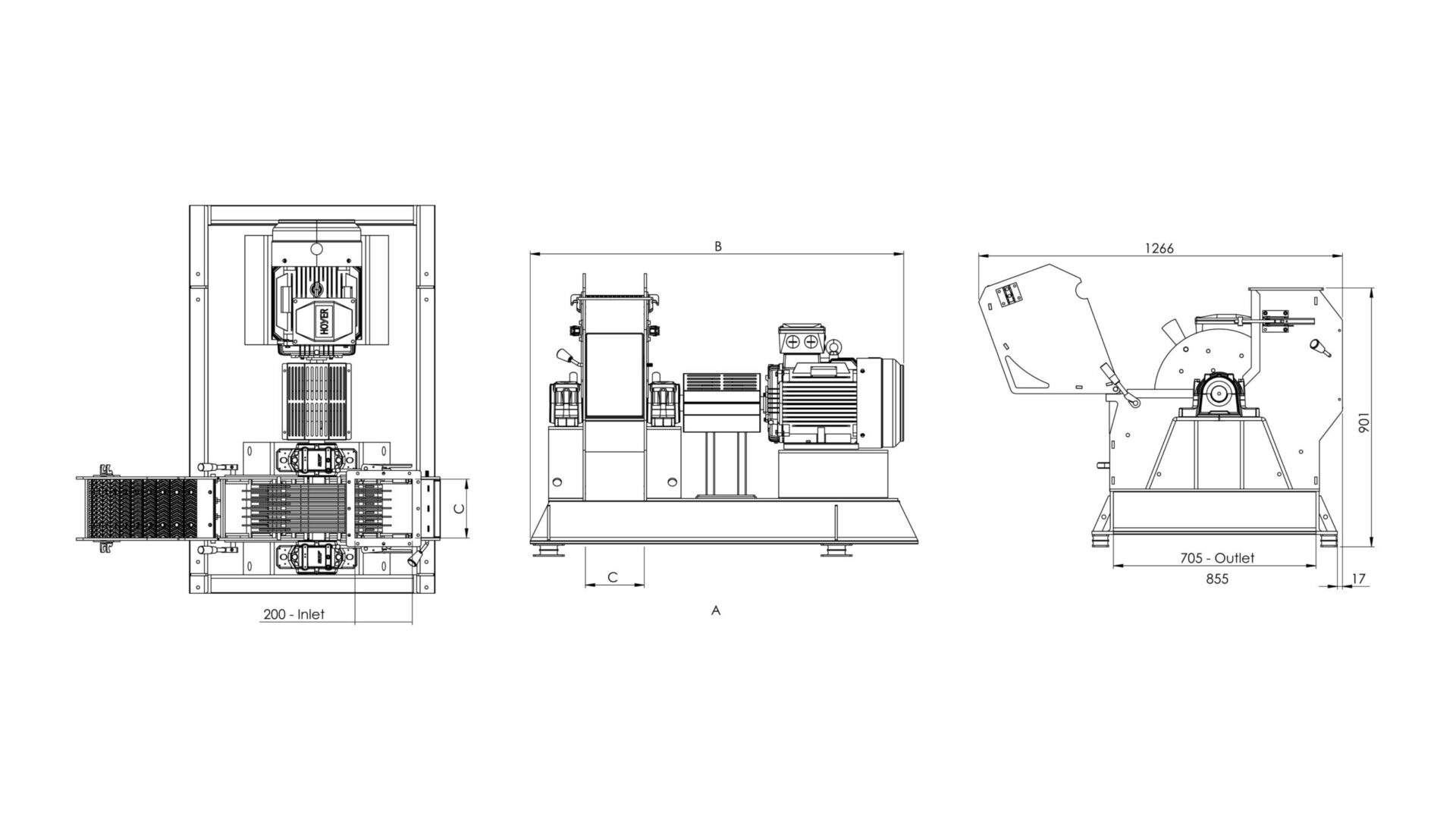

Euromilling’s Roller Mill HVS is a state-of-the-art grinding solution designed specifically for the rigorous demands of the North Sea oil and gas industry. Crafted from high-quality stainless steel, the Roller Mill HVS is engineered to crush drilling cuttings and grind hard materials found deep within the Norwegian underground. This robust machinery operates efficiently on multiple platforms in the North Sea, making it an indispensable tool for offshore drilling operations.

The Roller Mill HVS features two rollers coated with ultra-hard Wolframcarbid, rated at a hardness of 10 on the Mohs scale. These fixed rollers are synchronously driven, ensuring consistent and precise grinding without direct contact. The spacing between the rollers is adjustable, allowing for fine-tuning based on the specific requirements of the material being processed. This flexibility ensures the production of the finest dust particles, contributing to a cleaner and more efficient drilling process.

Key benefits of the Roller Mill HVS-300-300 include its durable construction and simple, safe technology. The machine's lubrication system minimizes maintenance needs, reducing production downtime and service costs. Operators can quickly initiate the grinding process, enhancing overall productivity. Furthermore, the Roller Mill HVS operates with a low noise level, promoting a more comfortable working environment and extending potential working hours.

Superior Performance and Safety with Euromilling Roller Mill HVS

Technical Data

Roller Mill Series