Offshore

Optimizing Drilling Waste Management with Euromilling's Mud Mill and Roller mill

Environmental regulatory considerations play a significant role in the overall economics of drilling a well. Euromilling recognizes the importance of efficient waste management and offers advanced solutions for grinding drilling waste, ultimately reducing operational costs associated with treatment and disposal. Our robust grinding equipment, specifically designed for the oil industry, ensures optimized handling and injection of drilling waste. By grinding the material, it becomes easier to handle and can be reinjected onsite, eliminating the need for transporting materials to an offsite disposal location.

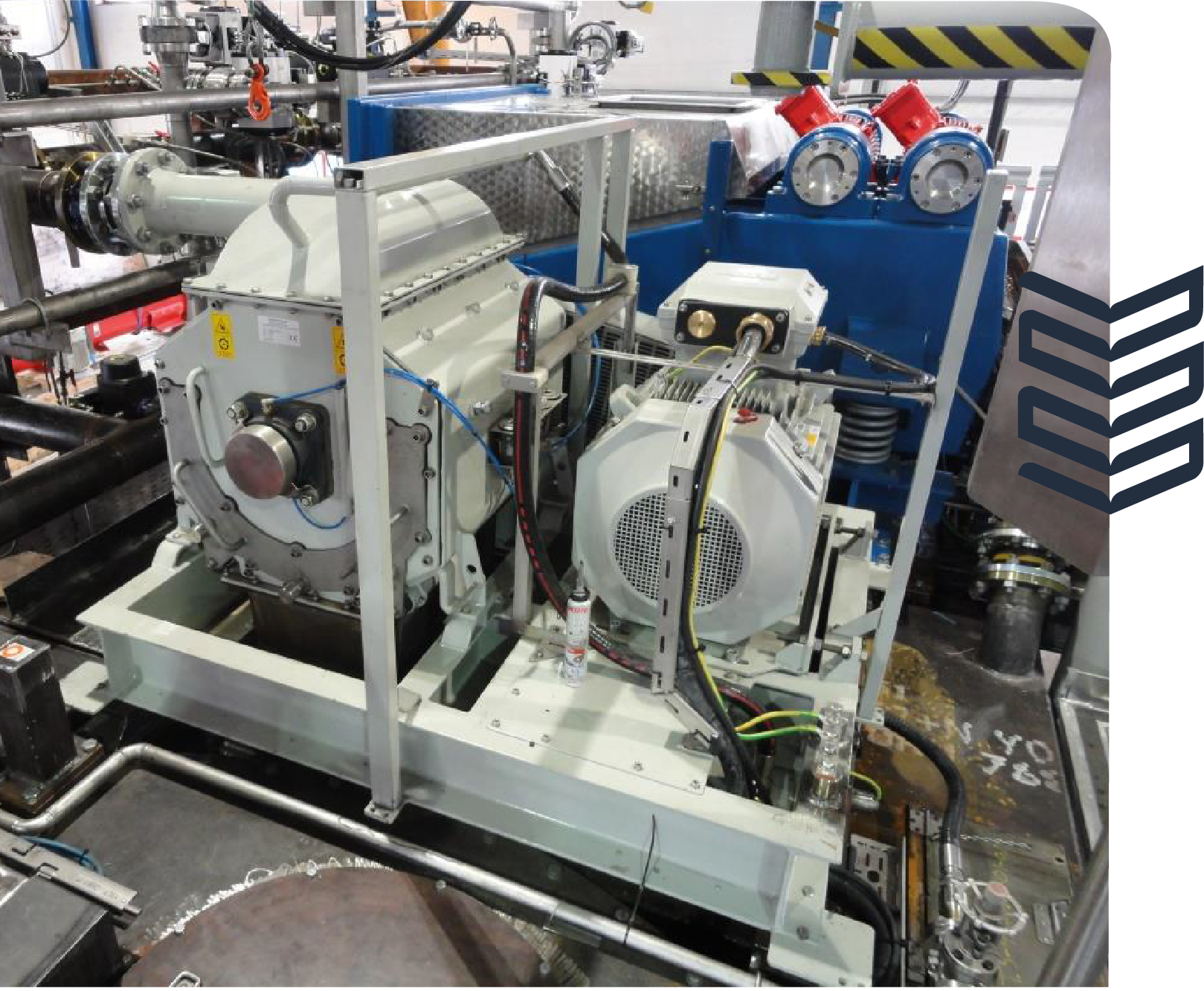

Euromilling has a proven track record in the North Sea, where our grinding equipment, including the MUD Mill HTS-700 and the ROLLER Mill HVS-300-300, is operational on several platforms. These mills grind mud and drill cuttings into small particles, facilitating reinjection and the creation of new mud. The MUD Mill HTS-700, made of durable steel, is specifically designed for crushing drilling cuttings. This technology not only reduces processing and transportation costs but also aligns with stringent environmental regulations by enabling onsite waste management.

Offshore

Innovative Features

of the Mud Mill

HTS-700

The MUD Mill HTS-700 from Euromilling is engineered for efficiency and longevity. This robust equipment features a rotor equipped with hard metal milling segments, capable of grinding material to sizes smaller than 3mm. The mill's design includes 18 milling segments on the rotor and 12 in the milling house, ensuring thorough grinding. The milling process occurs between these segments, and the mill can operate in both directions, enhancing its flexibility and efficiency.

Key advantages of the MUD Mill HTS-700 include a central lubrication system that minimizes maintenance requirements, reducing production stops and service costs. The mill is driven by 8 V-belts and an ATEX-approved ABB IE2 Motor (55-75kW) mounted on an adjustable console, ensuring reliable performance. The quick-change screen feature allows operators to swiftly initiate the grinding process, while the low noise level enables extended working hours near the mill.

Additionally, the mill's tray is supported by two large shafts, ensuring ease of operation and safety. The standard screen, with a thickness of 3mm and 3mm holes, guarantees precise grinding results. With no maintenance accessories needed, the MUD Mill HTS-700 is a cost-effective and reliable solution for efficient drilling waste management. Choose Euromilling's innovative technology to enhance your operational efficiency and environmental compliance in the oil industry.