Recycling

Euromillings Solutions for Wood Wool and Cellulose Insulation

At Euromillings, we offer comprehensive solutions for the production of wood wool insulation, starting from wood chips. Our advanced systems are designed to process wood chips into high-quality wood wool, an excellent insulating material that is naturally fire retardant and protected against insects and pests without the use of chemicals. Our complete solution ensures that the wood wool produced meets the highest standards of safety and efficiency, making it a reliable choice for various insulation applications. By utilizing state-of-the-art technology and equipment, we enable our clients to produce wood wool that offers superior thermal insulation properties while also being environmentally friendly.

Recycling

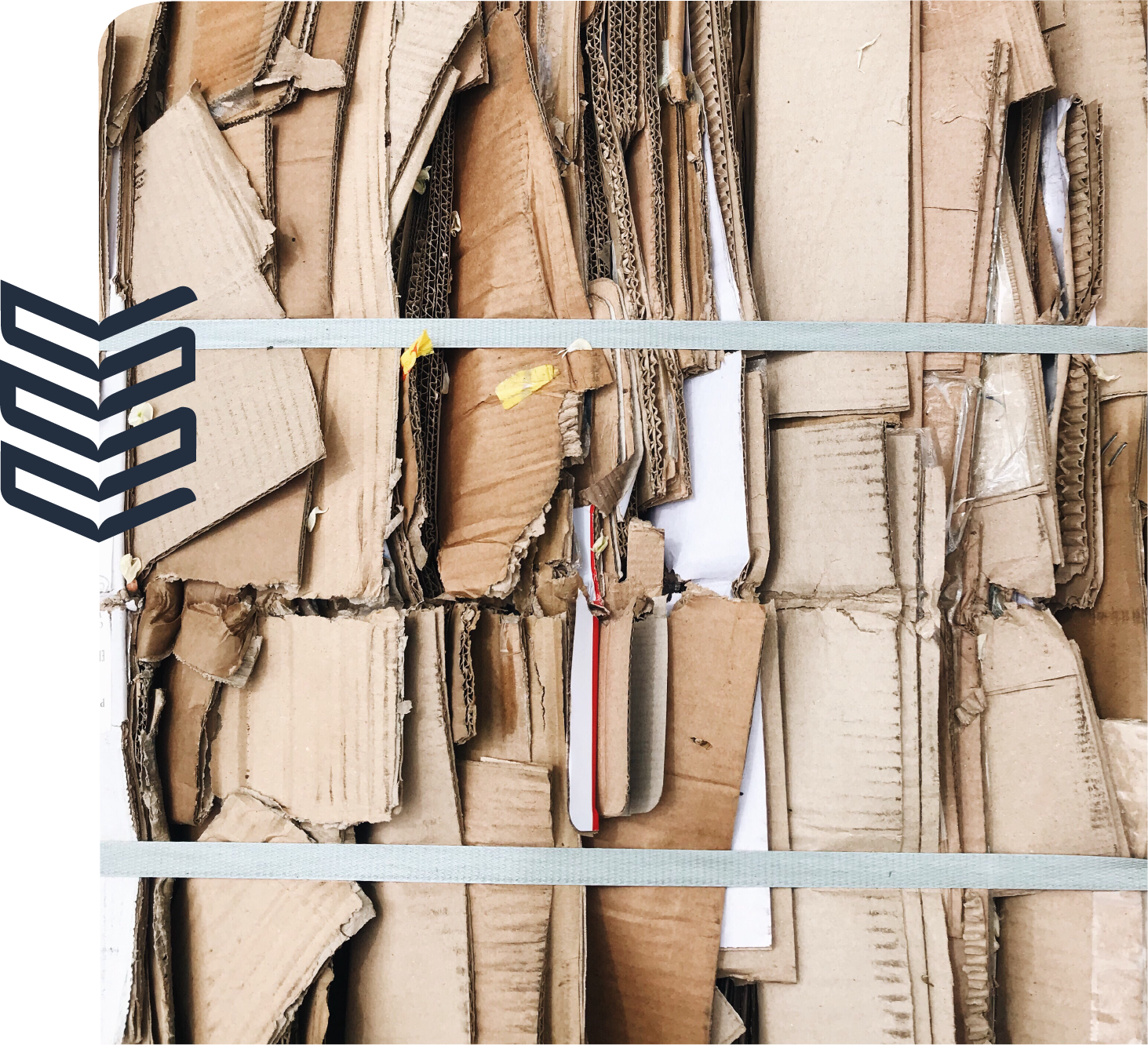

In addition to wood wool, Euromillings offers solutions for producing cellulose insulation from recycled paper, such as newspapers and cardboard. This process is particularly advantageous in today's context, where the volume of packaging materials from deliveries is significantly high. Converting these waste materials into cellulose insulation provides a sustainable solution that not only reduces landfill waste but also offers excellent thermal and acoustic insulation properties. Our machinery and technology are designed to efficiently convert paper waste into high-performance cellulose insulation, contributing to a circular economy and supporting environmental sustainability.

Environment

Environmental and Performance Benefits

Our solutions for wood wool and cellulose insulation are geared towards maximizing both environmental benefits and insulation performance. Wood wool insulation produced through our systems is inherently fire retardant and treated to resist insect and pest infestations without any chemical additives, ensuring long-lasting protection for buildings. This natural insulation material is also highly breathable, which helps in regulating indoor humidity and creating healthier living environments.

Cellulose insulation, on the other hand, leverages the recyclability of paper products, turning them into a valuable resource for building insulation. This approach not only reduces waste but also lowers the carbon footprint associated with manufacturing new insulation materials. The cellulose insulation produced by our systems is dense and effective at filling gaps and voids, providing excellent thermal resistance and soundproofing. By choosing Euromillings’ solutions, our clients can produce insulation materials that are both high-performing and environmentally responsible, aligning with modern sustainability goals and regulatory standards.

Reduce waste,

for a better future.

Years in the market

Mills extensive range

Countries

Hammer mills delivered

Biogas

Accelerating Biogas Production

Grind Your Biomass for Optimal Fermentation

Unlocking the full potential of biogas production requires a strategic approach. In this section, we explore the critical role that finely ground straw plays in speeding up the biogas production process, leading to a more efficient and sustainable energy generation.

Environment

The Finely Ground Straw Advantage

Biogas production, at its core, is a microbial digestion process. Microbes break down organic matter, like straw, into methane and carbon dioxide. To maximize this conversion, the key is to create optimal conditions for these microorganisms to thrive. That's where finely ground straw comes into play:

- Enhanced Surface Area: When straw is finely ground, it exposes a significantly larger surface area to the microbes. This increased contact area allows for quicker and more efficient decomposition.

- Faster Decomposition: The smaller straw particles are more readily accessible to the microorganisms, accelerating the breakdown process. This translates into faster biogas production.

- Consistent Feedstock: Uniformly ground straw ensures a consistent input material, promoting stable and predictable biogas output.