Euromilling hammermill unit HTG 250

February 20, 2020

Bag Dumping Station

August 3, 2020

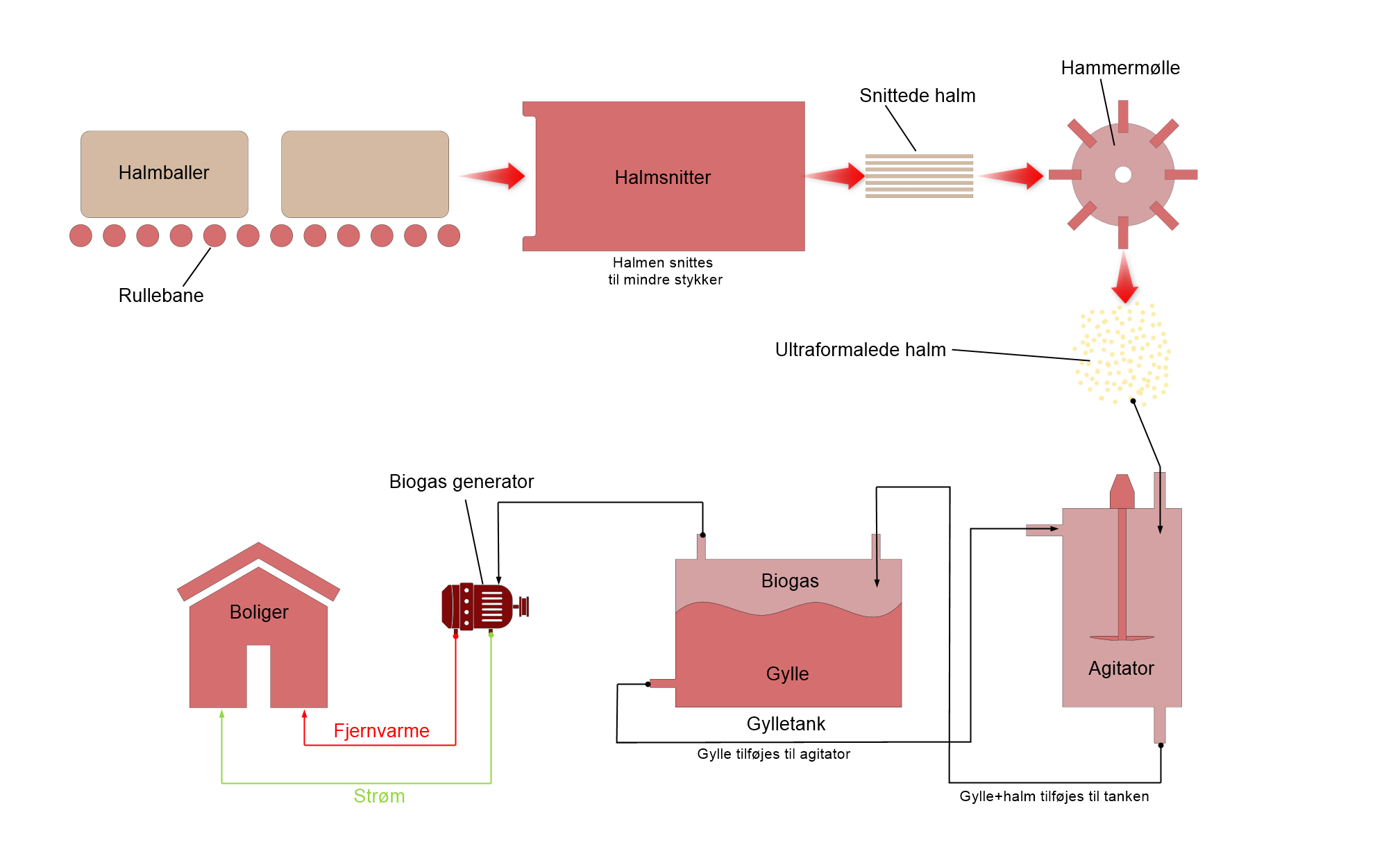

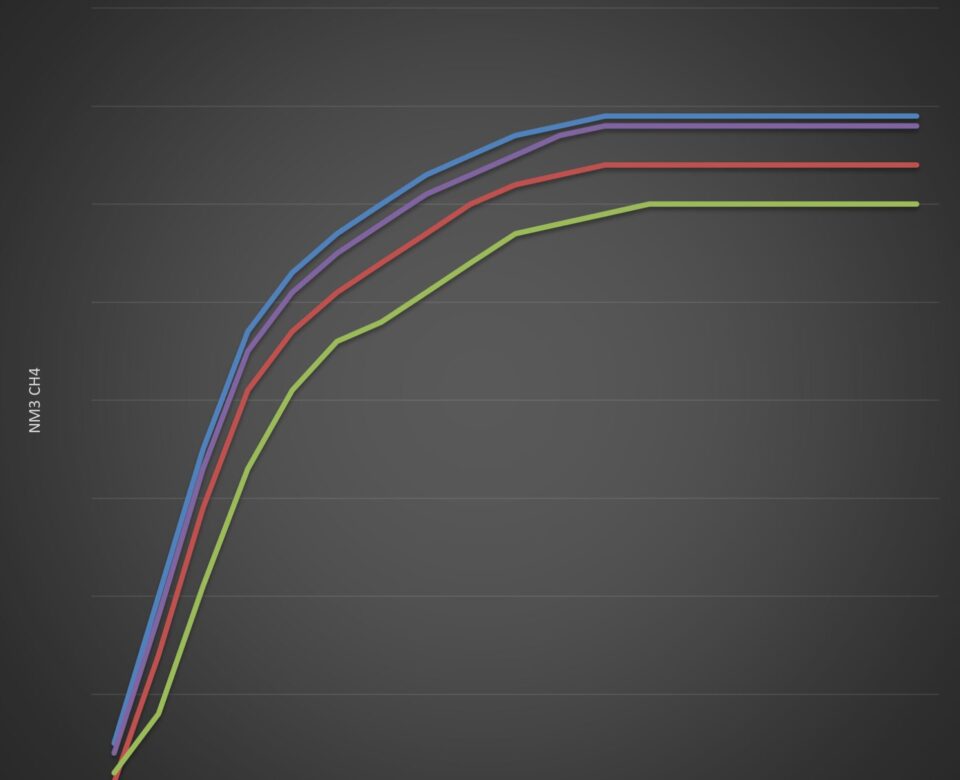

The project objective has been to optimise straw for biogas production. Straw is a plentiful resource with a strong potential for biogas production. Nevertheless, large amounts of straw are never used due to technical difficulties and low production yields. By shredding and subsequently grinding straw, we would be able to increase the straw production value from the producers' point of view. Processed in this way, straw will produce more gas per ton raw material, and the gas production will occur at a faster rate when the ground straw is mixed with slurry — thus improving the capacity of the biogas plant.

The aim has therefore been to develop new technical equipment for pre-grinding and handling straw for biogas production, an operation which is complicated by the water amount in the straw and by the relatively long straw fibres. The new equipment has been developed and implemented for further tests at project partner Lynggaard Biogasanlæg.

Article (In danish) from metalsuply

Article from Metalsuply Translated to english.

Euromilling Delivers Custom-Built Straw Handling System

Lynggården Biogas faced a challenge when two key suppliers pulled out.

At Lynggården Biogas, biogas has traditionally been produced from industrial products and slurry. However, when the two main suppliers of industrial products could no longer deliver as before, owner Peder Andersen made a quick decision.

- We previously received fibers from CP Kelco in Solrød and yeast residues from Novo Nordisk, but they are now building their own facilities, and Novo’s deliveries will stop in mid-2017. So, with what you might call timely foresight, I decided to start mixing straw into the slurry, explains Peder Andersen.

The straw to be mixed with the slurry comes from his own and nearby farmers' fields. The expectation is that not only dry straw will be used.

- I expect we can also use moist straw – Rasmus has assured me that the system can handle it, says Peder Andersen, who this year expects to mix 1,000 tons of straw into the slurry, next year 2,000 tons, and in the following years, 3,000 tons.

Not a Standard Product

Rasmus is Rasmus Jørgensen from the machinery manufacturing company Euromilling, which has custom-designed the straw handling system specifically for Lynggården Biogas.

- We’ve developed a straw handling system where straw is fed in from bales, which are then shredded, coarsely cut, finely ground to a particle size of under 2 mm, and then mixed with slurry. Finally, it’s pumped into the reactor tank, explains Rasmus Jørgensen.

And although Euromilling specializes in building machines, working on Lynggården Biogas' straw handling system has still been challenging and different.

- Working with straw is always challenging. It’s a difficult material to handle – fibrous, strong, and hard to break down. The challenge has also been to reduce it to a form that can be transported, Rasmus Jørgensen explains.

It took Euromilling four to five months to develop, design, and build the machine, which is quite normal for a machine of this caliber.

- Everything went as planned, but there has been a lot of development involved. This isn’t a standard product. The various elements are designed to handle the fibrous material, says Rasmus Jørgensen, emphasizing that they are ready to take on similar tasks in the future.

The Advantage of Straw in Slurry

Peder Andersen’s decision to mix straw into his slurry is driven by necessity, as industrial products are no longer available. But there’s a particular reason for choosing straw.

- I believe that agricultural crops grown in the fields should be used for livestock and humans, while by-products like straw are excellent for use in a plant, says Peder Andersen.

That said, there’s also another significant reason for choosing straw.

- He gets better efficiency from his gas plant by using straw compared to slurry. What’s special about our system is that it yields a very high gas extraction because the straw is so finely ground that it decomposes more easily. This results in a higher output compared to other methods of adding straw, explains Rasmus Jørgensen.

Additionally, slurry generates 20 cubic meters of gas per ton per year, while straw generates 400-450 cubic meters.

Ready to Start Soon

The system is complete and installed at Lynggården Biogas, but a few final touches are needed before the start button can be pressed.

- The electrician is working there now, and it’s mostly mechanically complete, but electrically and in terms of controls, we still have a bit to do. In two to three weeks, we should be ready to start, says Rasmus Jørgensen.

Lynggården Biogas is expected to produce enough gas in the future to generate 900 kW of electricity per hour – with a 90 percent utilization of the plant, of course.