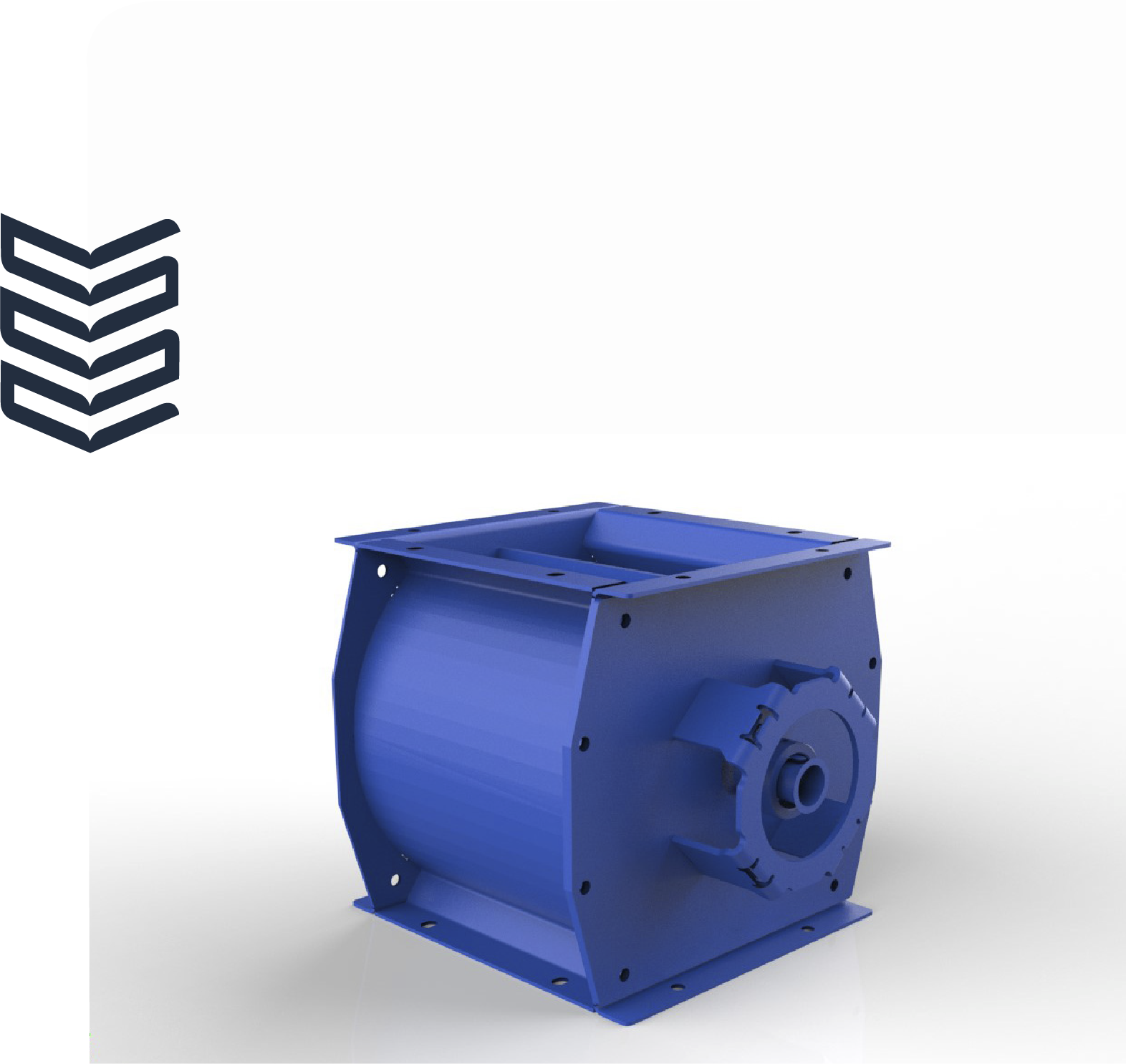

Versatile Rotary

Valves for Diverse Industrial

Applications

Euromilling offers a comprehensive range of rotary valves designed to meet the varied needs of different industries. Our rotary valves are engineered for the efficient feeding and unloading of granular and powdered products, making them suitable for use in pneumatic conveying lines, under cyclones, or at filter exhausts. Crafted from robust materials such as cast iron, nickel/chromium plated cast iron, and stainless steel AISI316, our valves ensure durability and reliability even in demanding environments.

Our rotary valves are versatile, with several rotor types and configurations to handle any product or special customer requirement. They are available with bare shafts or motorization options, including gearmotors and variable speed gearmotors, complete with chain guards to comply with CE regulations. This flexibility allows our rotary valves to integrate seamlessly into existing systems and meet specific operational needs.

One of the standout features of our rotary valves is the quick disassembly design, ideal for industries requiring frequent cleaning of the rotor and internal components. This feature significantly reduces downtime and optimizes operational efficiency, allowing for swift maintenance and ensuring that production processes remain uninterrupted.

Rotary Valves

Our valves are capable of handling high temperatures up to 220°C, with special versions available for even higher temperatures on request. Equipped with external steel supports and packing glands, our rotary valves maintain excellent airlock and product flow, ensuring smooth and efficient pneumatic conveying.

For industries with stringent safety requirements, we offer rotary valves designed for explosive atmospheres. These valves comply with rigorous European norms for explosion isolation systems and are certified for resistance to high pressures. They are available in various materials, including cast iron, stainless steel, and with options for nickel or chromium plating.

Choose Euromilling's rotary valves for a reliable, adaptable, and efficient solution to your material handling needs. Our commitment to quality and versatility ensures that our rotary valves can meet the demands of any industrial application, providing peace of mind and optimal performance.

Blow Through Rotary Valves for Efficient Pneumatic Conveying

At Euromilling, our blow through rotary valves are designed to excel in the pneumatic conveying of high-temperature products, accommodating temperatures up to 220°C, with special executions available for even higher temperatures upon request. These robust valves feature steel supports and bearings placed completely outside, equipped with packing glands to ensure optimal performance and durability.

Our "SF" type blow through rotary valve is ideal for feeding and conveying products in grain and powder form across various industrial sectors that utilize pneumatic conveying lines with average to low pressure. The meticulous construction, multiple rotor types, and minimal tolerances guarantee an excellent airlock and smooth product flow within pneumatic conveying systems.

Crafted from high-quality materials including cast iron, nickel/chromium plated cast iron, or stainless steel AISI316, these valves are equipped with flange connections on both sides. They are available either with a bare shaft or with motorization options that include variable speed gearmotor or gearmotor and complete drive with chain guard, all conforming to CE standards.

Our blow through rotary valves are versatile and suitable for breaking, dosing, and pneumatic transport of powders and granules of all types in the food, chemical, and plastics industries, across low, medium, and high-pressure lines. Each valve is designed to meet the specific requirements of our customers, ensuring reliable and efficient performance in every application.

For more information, contact us directly to discuss how our blow through rotary valves can enhance your pneumatic conveying processes.