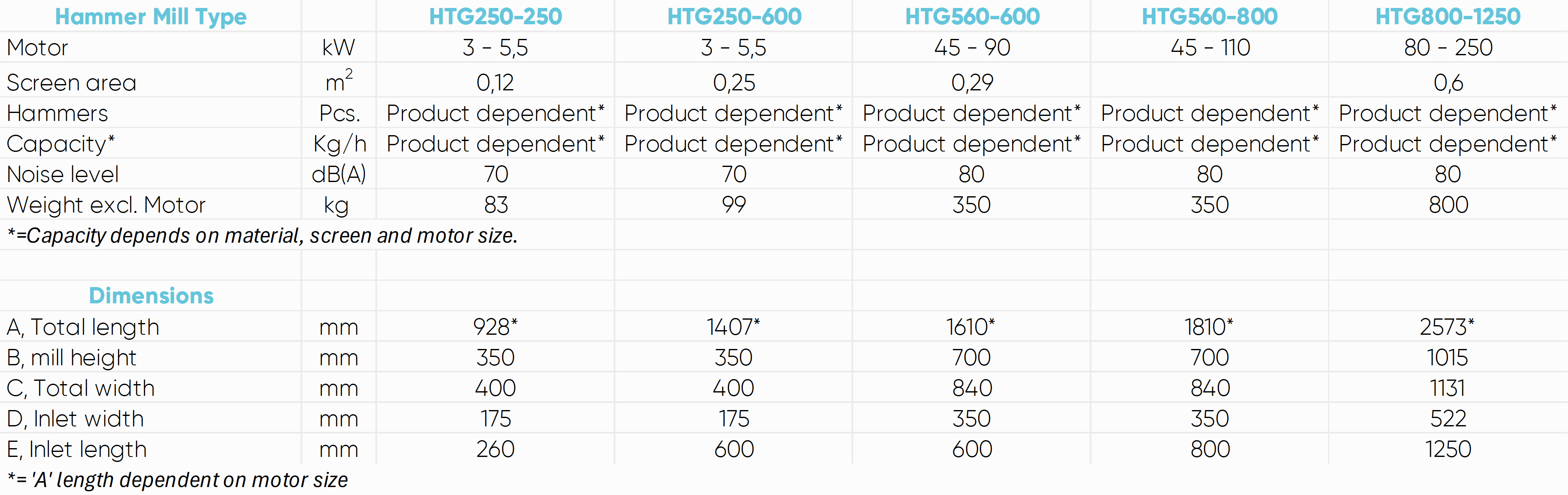

HTG Series

Euromilling’s Line of Granulators

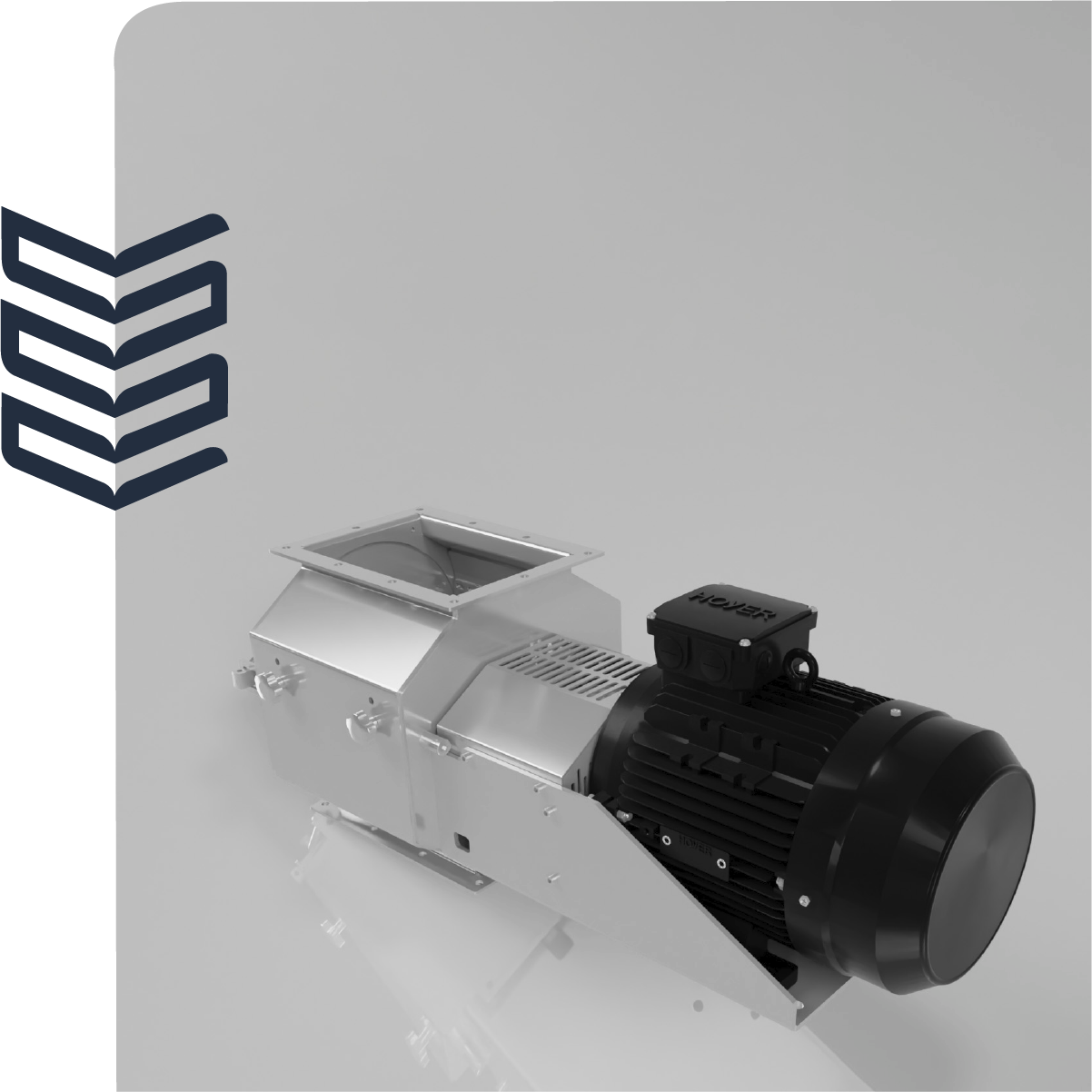

The HTG 800-1250

Granulator

The HTG 800-1250 granulator is equipped with a hydraulic drawer for quick change of rotor. The granulator is used for granulation tasks in industry, it is particularly suitable for installation in pipe systems with air transport. The process consists in the raw material being led to the granulator's inlet at the top of the granulator housing, the product is then broken into pieces using the rotation of the granulator wings and friction against the grinding bridge and screen. The material is then directed to the lower part of the granulator.

Manufactured in AISI304 or AISI316.

ATEX Certification

ATEX certification is given to equipment that has gone through rigorous testing outlined by European Union directives. Products that are ATEX compliant have been proved safe to use in specific environments with explosive atmospheres, according to the zone/s they are certified to be used in.

The European Union has mandated that ATEX compliance is necessary wherever a potentially explosive atmosphere exists in order to keep workers safe. These atmospheres are characterized by possessing three things.

- air

- an ignition source

- one of the following three substances:

- flammable gases

- mists or vapor

- combustible dust

Products that have received ATEX certification will have the official “Ex” badge, indicating they are safe in explosive atmospheres.

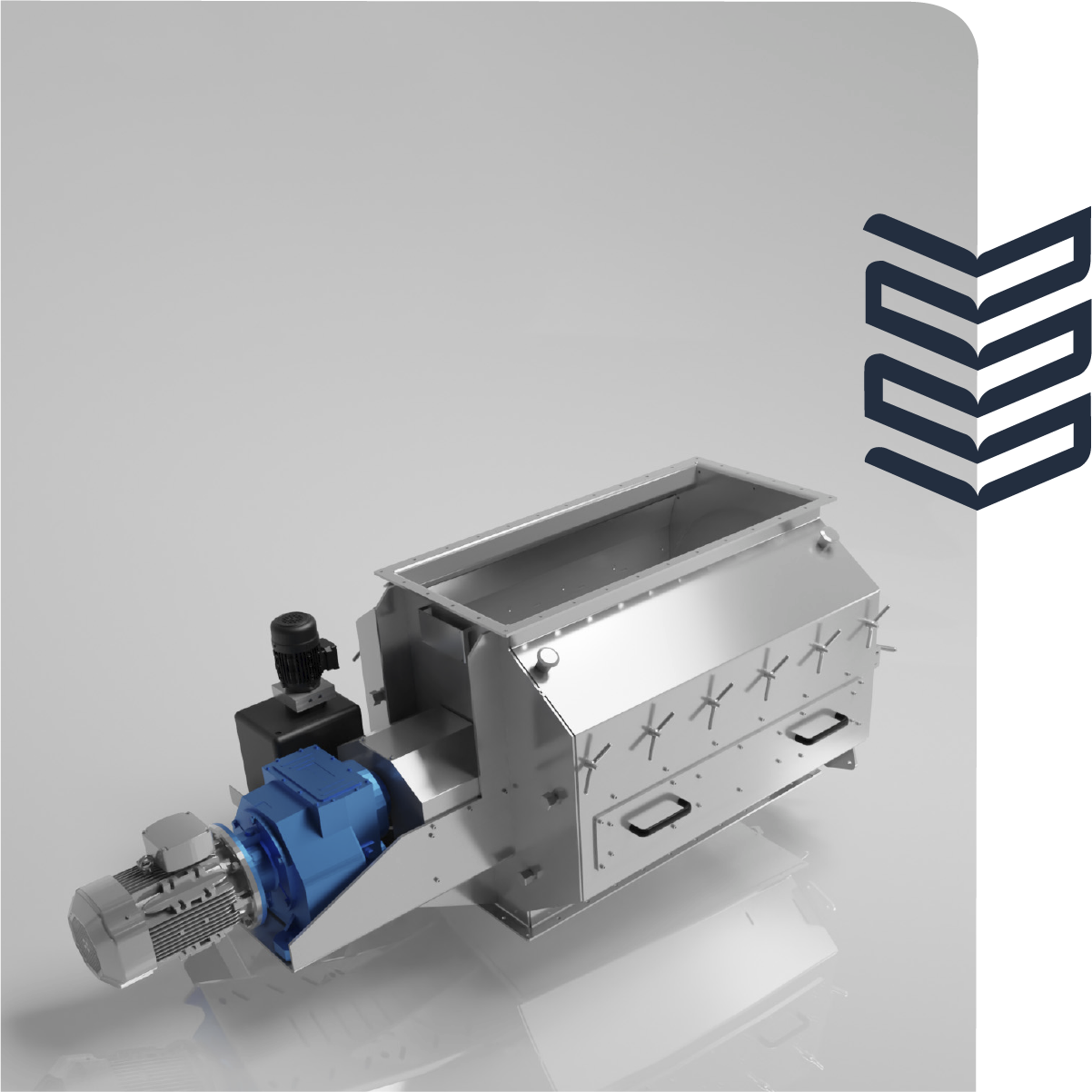

Total Solutions

for the Food

Industry.

In conjunction with their hammer mills, EUROmilling's granulators provide tailored solutions for size reduction in the food industry. Engineered for efficiency, these granulators excel in breaking down larger particles into the desired size range without compromising the integrity of the product. The versatility of EUROmilling's granulators allows for customization, ensuring compatibility with a wide array of food processing applications.

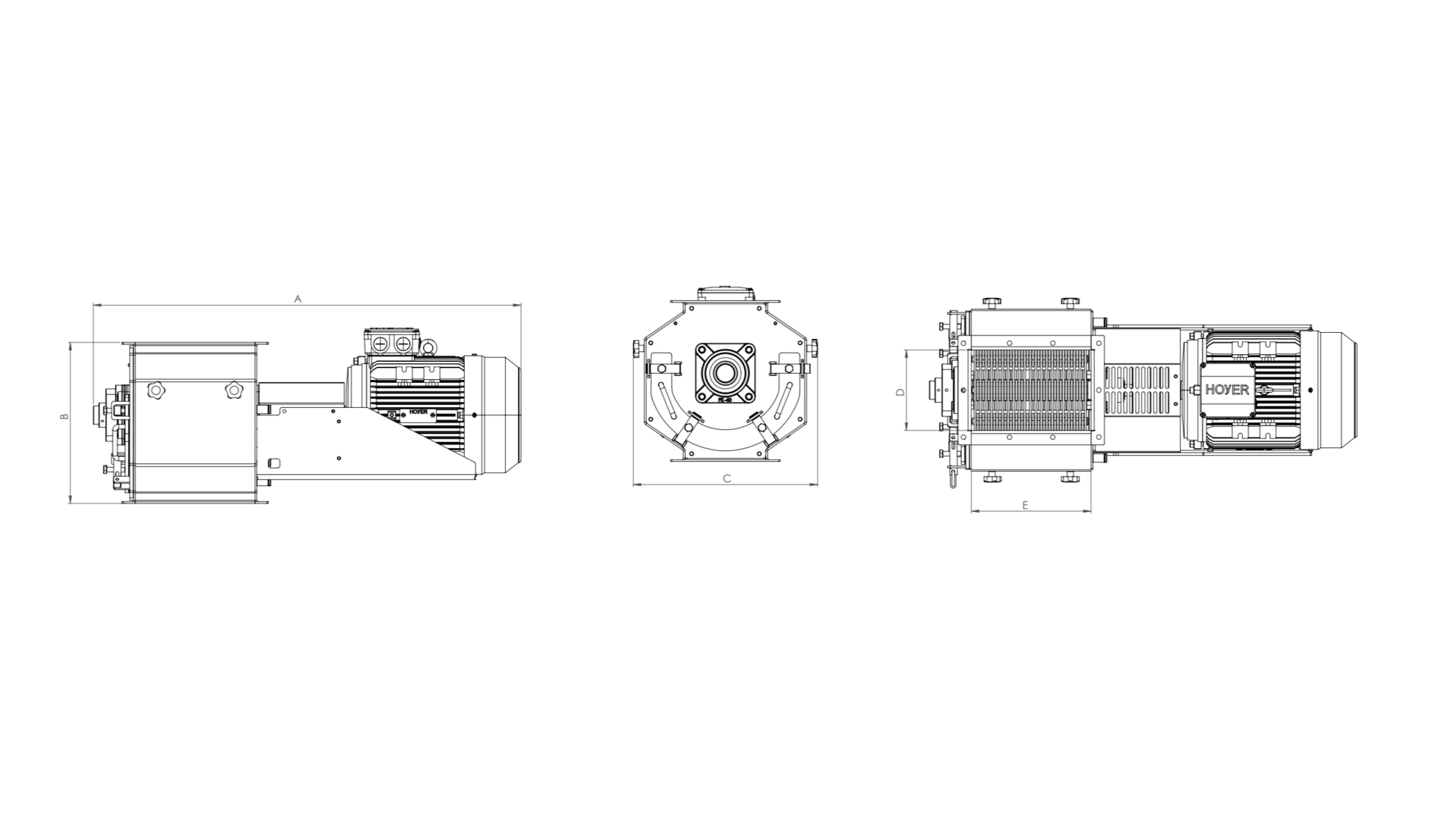

Technical Data

HTG Series