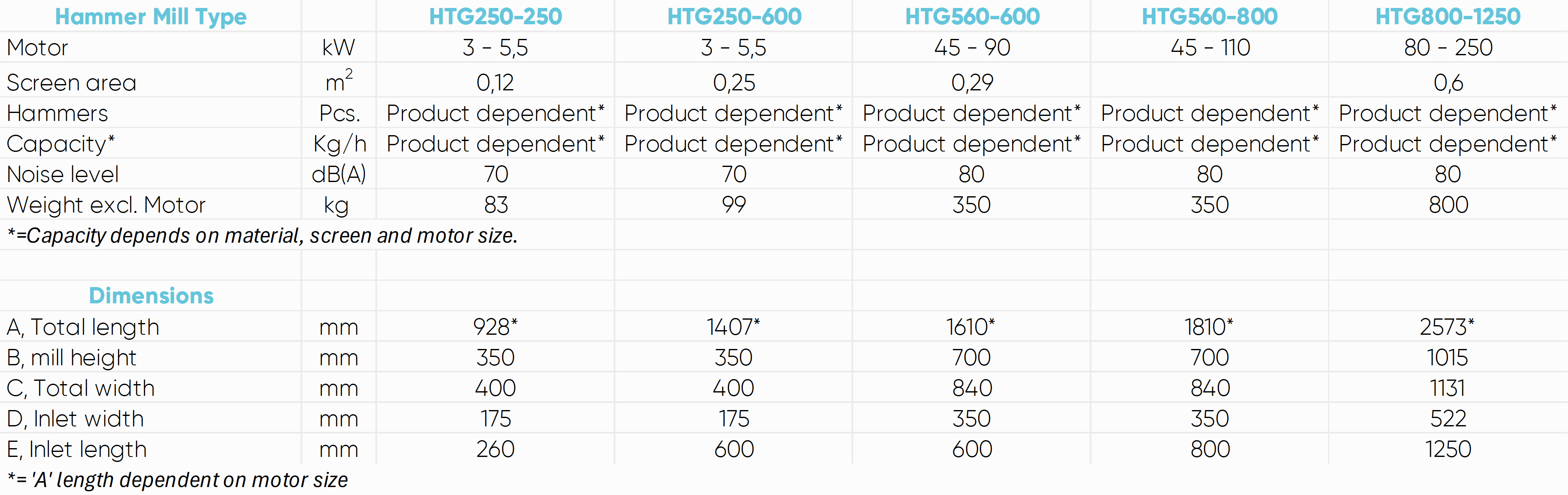

HTS Series

The HTS 250 Hammer mill is equipped with a screen drawer for quick change of screens. The hammer mill is used for grinding tasks in industry, it is particularly suitable for installation in pipe systems with air transport. The process consists of the raw material being led to the hammer mill's inlet at the top of the mill house. The product is then broken into pieces by means of the hammer's rotation and friction against the grinding bridge and sieve.

The material is then directed to the lower part of the mill. Manufactured in AISI304 or AISI316.

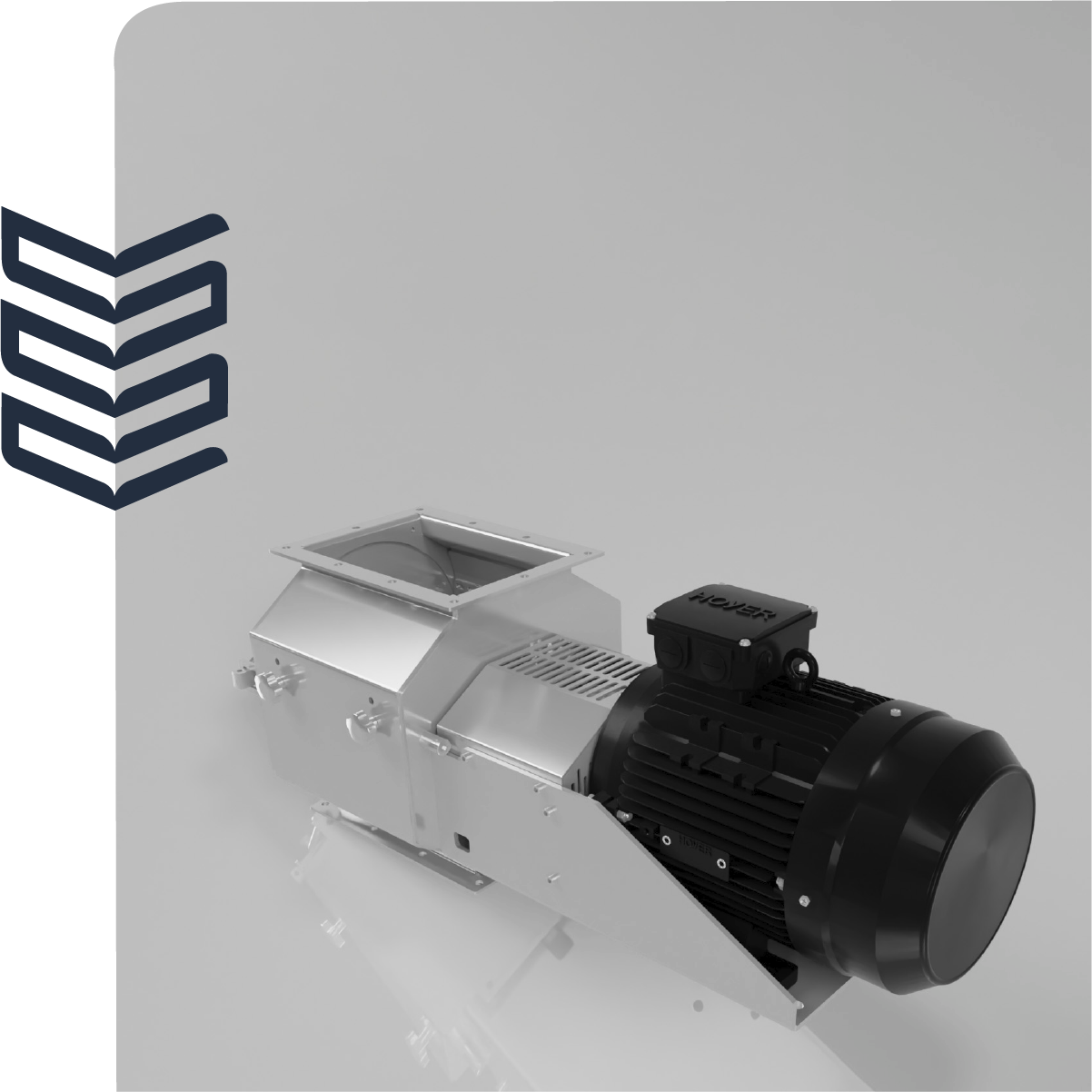

HTS 560-800

The HTS 560-800 Hammer mill is equipped with a screen drawer for quick change of screens. The hammer mill is used for grinding tasks in industry, it is particularly suitable for installation in pipe systems with air transport. The process consists of the raw material being led to the hammer mill's inlet at the top of the mill house. The product is then broken into pieces by means of the hammer's rotation and friction against the grinding bridge and sieve.

The material is then directed to the lower part of the mill. Manufactured in AISI304 or AISI316.

ATEX Certification

At Euromilling, we prioritize safety and regulatory compliance through our advanced ATEX solutions. Our comprehensive approach includes certified ATEX solutions, thorough risk analysis, and detailed documentation, providing a robust foundation for your operations.

Meeting Regulatory Standards

Euromilling’s ATEX solutions are meticulously designed to meet all regulatory standards, ensuring that your operations comply with the strictest authority requirements. Our teams of engineers and project managers work closely with industry professionals to deliver unparalleled safety and compliance.

Key Components of Our ATEX Solutions:

-

Risk Assessment: We conduct in-depth evaluations of potential risks associated with your project, developing straightforward strategies to ensure your operations are safe and successful. Our proactive approach to risk management sets the foundation for a secure working environment.

-

ATEX Compliance: We guarantee that your facility adheres to the ATEX directive, ensuring the safe handling of potentially explosive atmospheres. Our solutions are designed to minimize the risk of explosions and ensure the highest levels of safety.

-

CE Certificate Acquisition: Our experts assist you in obtaining the CE certificate, validating that your operations comply with essential health and safety requirements. This certification reflects our commitment to delivering solutions that meet the highest standards of quality and safety.

-

Fire Extinguishing Systems: For added safety, we implement state-of-the-art fire extinguishing systems tailored to your specific needs. These systems provide an additional layer of protection for your operations.

Additionally, Euromilling offers consultancy services for both existing and new projects, providing expert assistance with ATEX solutions to ensure full compliance and optimized safety.

Euromilling's ATEX solutions are trusted by the biomass and food industry for their reliability and effectiveness. Partner with us to ensure your operations are safe, compliant, and prepared for any challenge.

Total Solutions

for the Food

Industry.

Ever since our founding in 1994, we have manufactured process equipment for the food industry, building extensive experience in supplying equipment and total solutions to the sector. We guarantee that the food contact material is manufactured in accordance with current legislation: intended for contact with food.

Our complete plants include equipment for shredding, milling, mixing, storage, weighing, dosing, as well as mechanical and pneumatic transport of various materials, ingredients, and powders for the food industry.

Euromilling designs and manufactures equipment and total solutions with Clean-in-place (CIP) technology

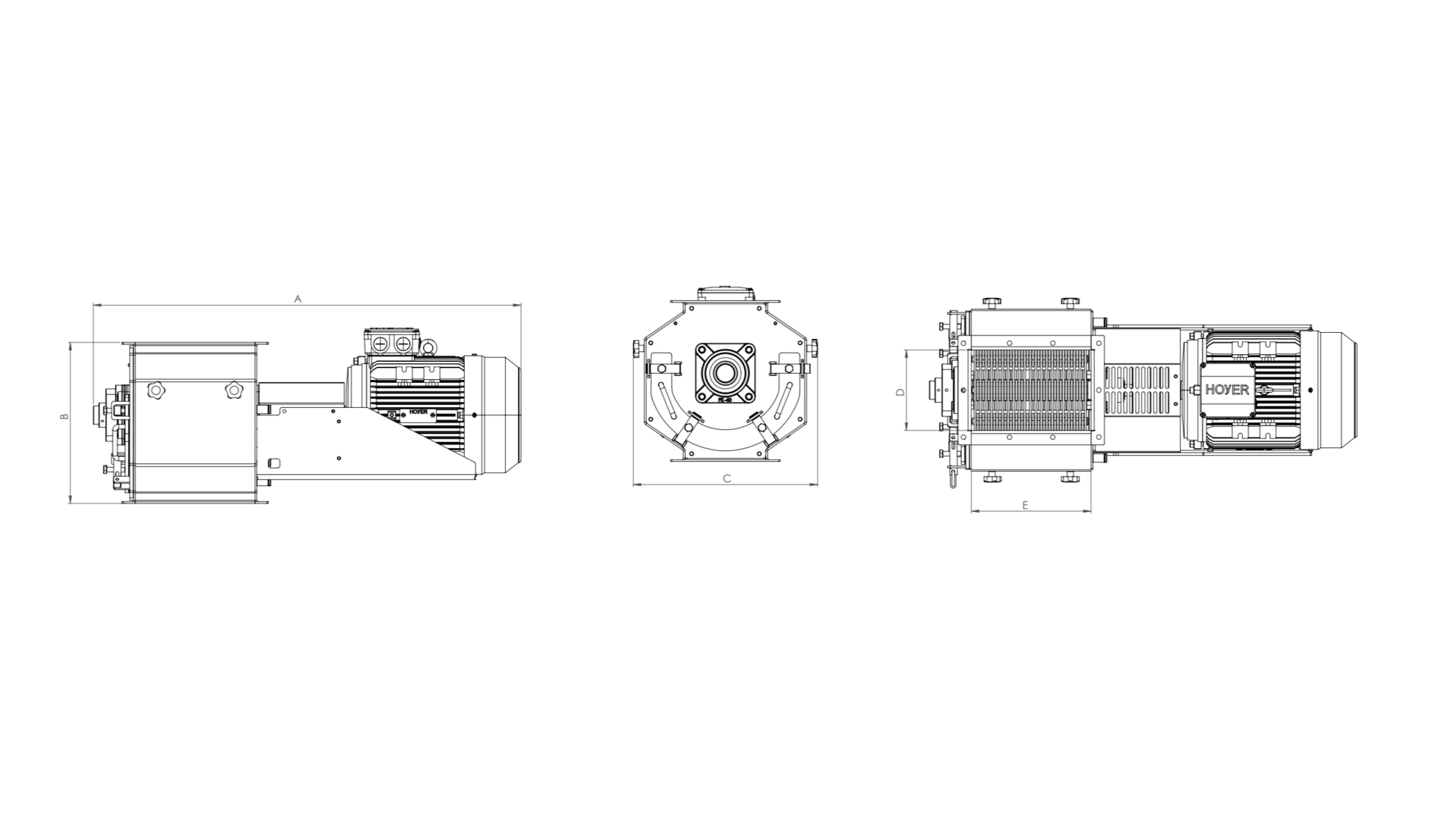

Technical Data

HTS Series