EUROmilling and Salmatec: Joining Forces for Retail

Success in Milling Solutions

EUROmilling is delighted to announce a new partnership with Salmatec, renowned for their top-quality pill presses. This collaboration opens up a world of possibilities as we aim to provide you with comprehensive solutions for all your milling needs.

As part of this exciting development, Euromilling now has the privilege of offering complete solutions to the industry through our association with Salmatec. This means that you, our valued customers, can benefit from a one-stop-shop experience for all your milling requirements.

Cost-effective and

Safe to Operate

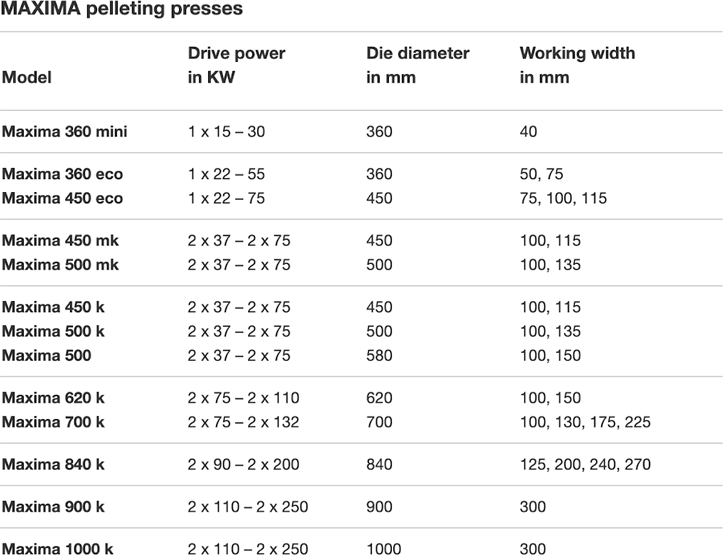

SALMATEC pelleting presses from the Maxima series have a modular design and can be adapted perfectly to the most diverse requirements.

The different operating conditions that a pelleting press is subjected to during production of pellets make high demands on construction and production.

That’s why SALMATEC pelleting presses are made exclusively of high-quality materials and of course comply with the latest safety standards and guidelines.

The capacity per hour may amount to up to 50t depending on the type of machine and area of application.

Comprehensive

Equipment

All Maxima pelleting presses have a vertically operating ring die in which two or three rollers depending on the product being processed ensure the highest pressure. The Maxima pelleting presses have a low-noise and one-step operated v-belt drive which provides energy-efficient and equal power transmission.

The heart of our pelleting press, the generously sized spherical roller bearing of the rotor, provides the machine with sufficient reserves even under relatively high stress.

The access door can be swung open across the entire pressing room and offers the best possible access to the pressing tools.

All Maxima pelleting presses have comprehensive standard and safety equipment. This includes the overload flap, permanent magnets, shear pins and overload clutches, temperature control, safety switches and much more.

Technical Data

MAXIMA Pellet Press